1

/

of

5

Trocen Anywells AWC708C LITE Laser Controller for Co2 Laser Engraving Cutting Machine Replace AWC608

Trocen Anywells AWC708C LITE Laser Controller for Co2 Laser Engraving Cutting Machine Replace AWC608

Regular price

$220.00 USD

Regular price

$220.00 USD

Sale price

$220.00 USD

Unit price

/

per

Couldn't load pickup availability

Trocen Anywells AWC708C LITE Laser Controller for Co2 Laser Engraving Cutting Machine Replace AWC608

Product Description

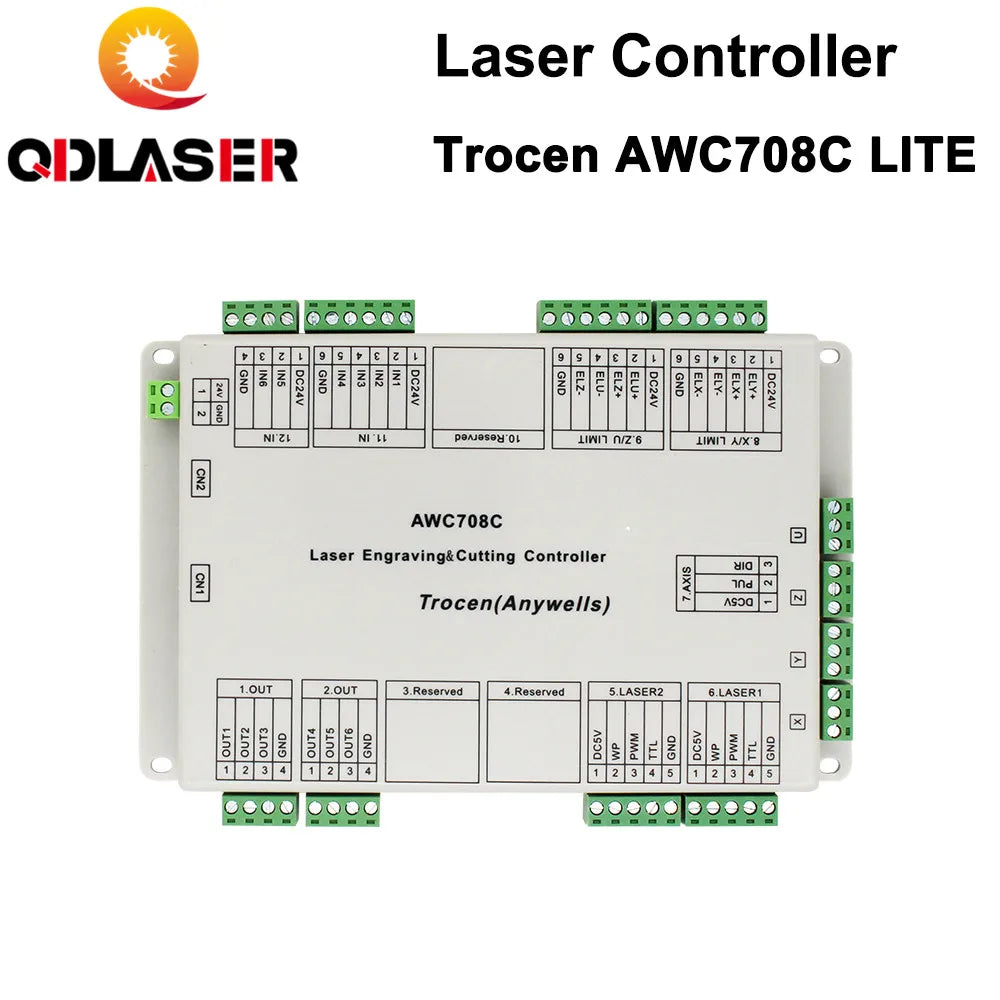

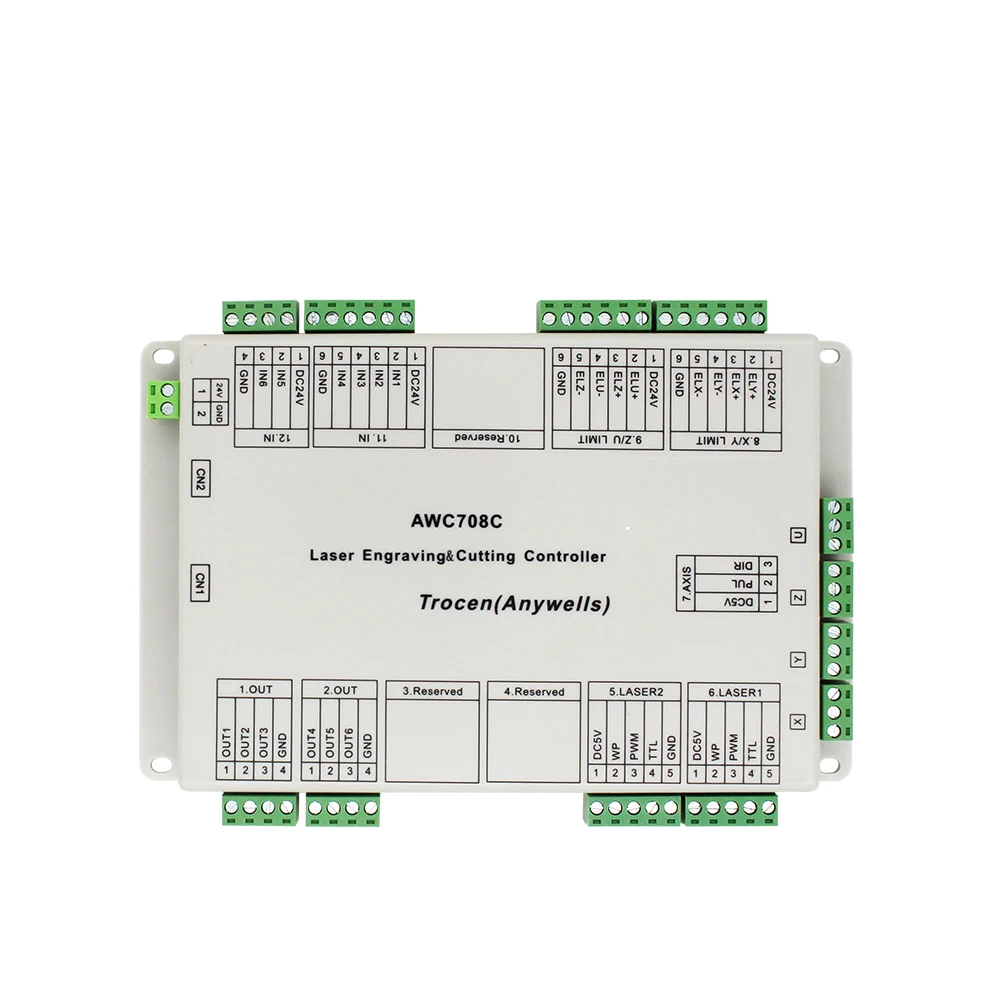

1.AWC708C LITE replace AWC608:

AWC708C LITE basis AWC608C based on the outstanding features, for the majority of laser engraving / cutting machine manufacturers

supporting the high-end laser engraving machine / laser cutting machine / laser drilling machine control system. High-speed

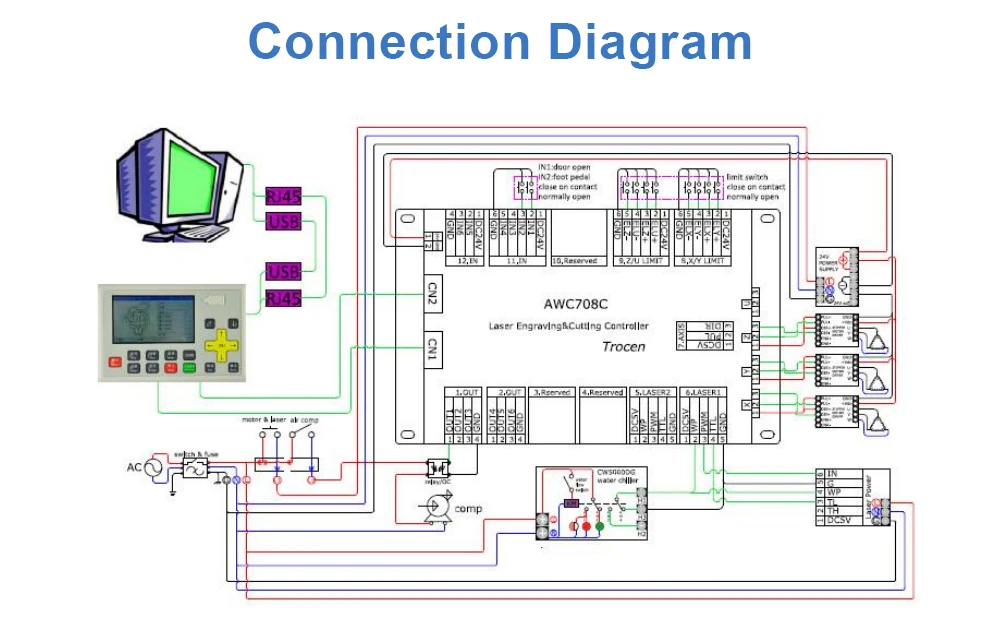

cutting without jagged, true color screen, can directly preview processing graphics. Data transfer can be managed via a USB cable,

U disk, network interface. With a 2-way laser power

2.Technical parameters:

Power motor type maximal exercise coordinate support laser intensity laser scope

X YZ U-axis accuracy

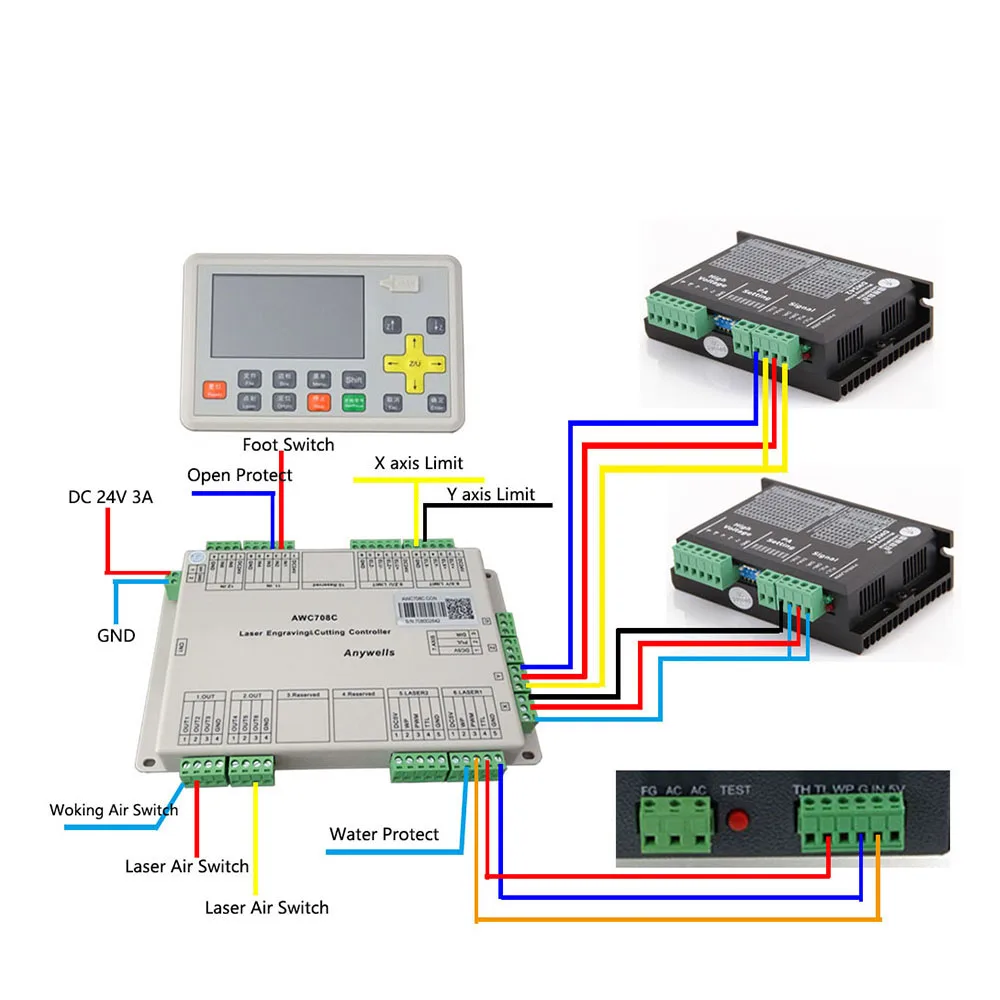

DC 24V, 2A stepper motor

Servo motor depending on customer requirements ± 0.001 mm variety of DC excitation, RF excited CO2 laser solid-state lasers from 0

to 100%

0.01% continuously adjustable laser cutting machine

Laser Engraving Machine

Stimulate

3.Features:

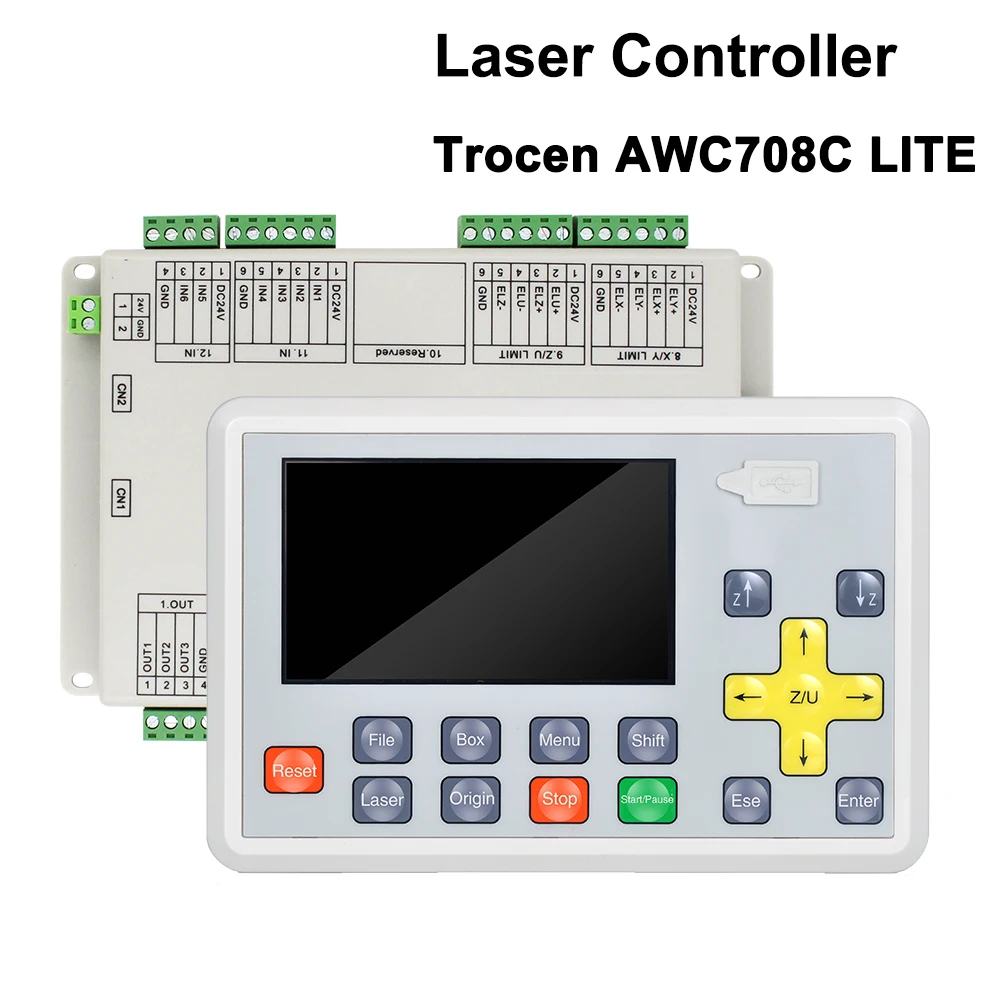

4.3 inches true color, visual display, and lead the industry a new direction.

Control core uses 32 high-speed floating-point embedded DSP, clocked at up to 150MHZ; PC settings can be completely divorced from

the device parameters, all completely isolated optocoupler external electromagnetic interference, the system is reliable, U disk

upgrade program to update the motherboard.

Full use of advanced S-shaped acceleration and deceleration algorithm, support lines, arcs and B-spline interpolation; with a

smooth high-speed motion, speed variation characteristic soft; and ultimately achieve high-speed cutting without jagged effect.

Support USB2.0 interface, U disk read and write files.

Network management, and PC communication more convenient, safe and reliable. Use the USB cable industry dropped solve problems.

128MB onboard memory. Can be run independently from the PC, user-friendly high-volume engraving / cutting production.

Can achieve high-speed four-axis control

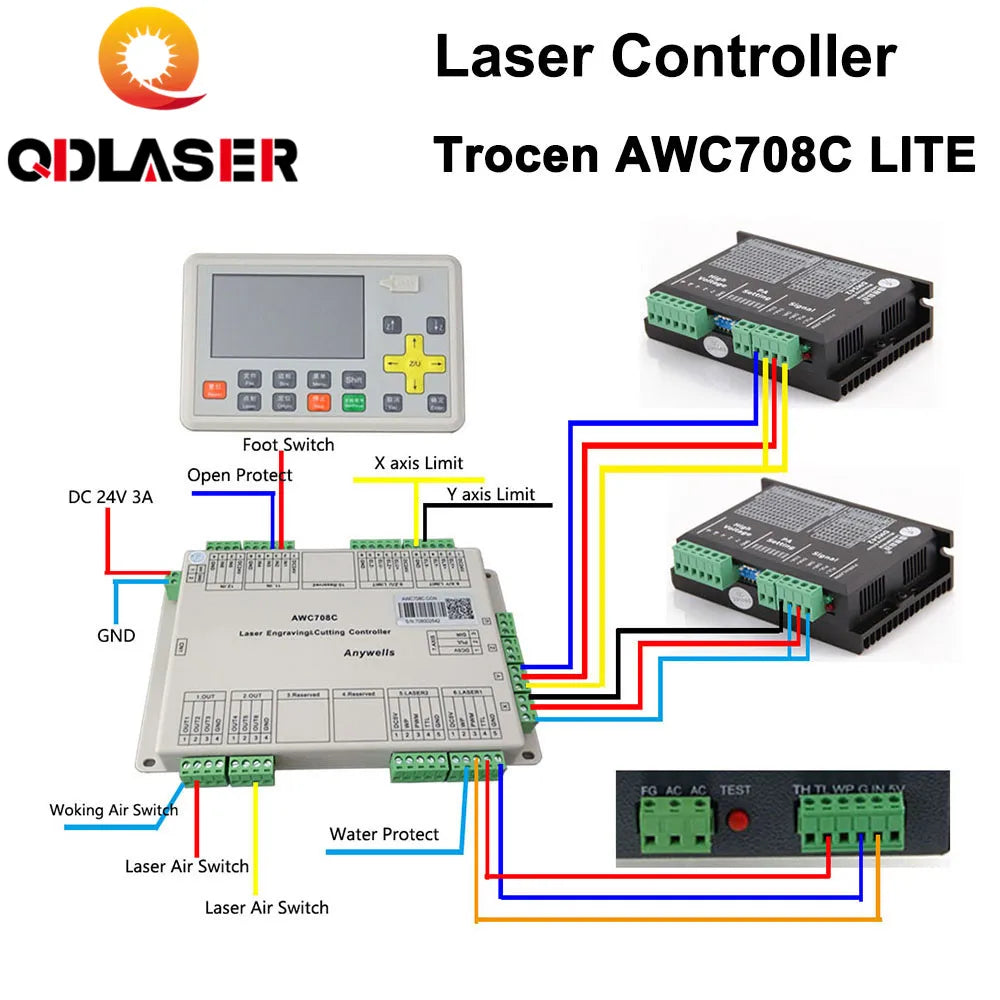

Just add different motor drive system can control servo, stepper and other sports organizations.

Support automatic inflatable, autofocus, foot switches, security and other functions.

Optional soft / hard limit coordinate protection.

Support Road laser control, power individually adjustable, and can control a variety of lasers;

Mutual support industry advanced double shift cut, greatly saving processing time and processing materials.

When introducing any angle cutting can increase the export line to ensure smooth cutting seams. Flexibility to set small round cut

speed and improve the effect of cutting small circle.

The output data can be layered, can be defined individually for each output power, output speed, the laser method (cutting,

carving, sculpture slope, etc.), and the definition of each parameter is automatically saved.

Sound continued carving off function: real-time recording system work working condition, after a sudden power failure before

restarting the machine can continue to power down the unfinished work.

Estimated processing time and cost budgets, intelligent layout input.

Engraving / cutting full-featured, engraving, cutting a variety of modes can complete the job.

Cutting the state of the cutting path to follow in real time

With a real clock display

Free delivery for Windows-based control software LaserCAD, CorelDraw and AutoCAD direct output software (support PLT, AI, BMP,

DST, DSB, DXF formats).

AWC708C LITE basis AWC608C based on the outstanding features, for the majority of laser engraving / cutting machine manufacturers

supporting the high-end laser engraving machine / laser cutting machine / laser drilling machine control system. High-speed

cutting without jagged, true color screen, can directly preview processing graphics. Data transfer can be managed via a USB cable,

U disk, network interface. With a 2-way laser power

2.Technical parameters:

Power motor type maximal exercise coordinate support laser intensity laser scope

X YZ U-axis accuracy

DC 24V, 2A stepper motor

Servo motor depending on customer requirements ± 0.001 mm variety of DC excitation, RF excited CO2 laser solid-state lasers from 0

to 100%

0.01% continuously adjustable laser cutting machine

Laser Engraving Machine

Stimulate

3.Features:

4.3 inches true color, visual display, and lead the industry a new direction.

Control core uses 32 high-speed floating-point embedded DSP, clocked at up to 150MHZ; PC settings can be completely divorced from

the device parameters, all completely isolated optocoupler external electromagnetic interference, the system is reliable, U disk

upgrade program to update the motherboard.

Full use of advanced S-shaped acceleration and deceleration algorithm, support lines, arcs and B-spline interpolation; with a

smooth high-speed motion, speed variation characteristic soft; and ultimately achieve high-speed cutting without jagged effect.

Support USB2.0 interface, U disk read and write files.

Network management, and PC communication more convenient, safe and reliable. Use the USB cable industry dropped solve problems.

128MB onboard memory. Can be run independently from the PC, user-friendly high-volume engraving / cutting production.

Can achieve high-speed four-axis control

Just add different motor drive system can control servo, stepper and other sports organizations.

Support automatic inflatable, autofocus, foot switches, security and other functions.

Optional soft / hard limit coordinate protection.

Support Road laser control, power individually adjustable, and can control a variety of lasers;

Mutual support industry advanced double shift cut, greatly saving processing time and processing materials.

When introducing any angle cutting can increase the export line to ensure smooth cutting seams. Flexibility to set small round cut

speed and improve the effect of cutting small circle.

The output data can be layered, can be defined individually for each output power, output speed, the laser method (cutting,

carving, sculpture slope, etc.), and the definition of each parameter is automatically saved.

Sound continued carving off function: real-time recording system work working condition, after a sudden power failure before

restarting the machine can continue to power down the unfinished work.

Estimated processing time and cost budgets, intelligent layout input.

Engraving / cutting full-featured, engraving, cutting a variety of modes can complete the job.

Cutting the state of the cutting path to follow in real time

With a real clock display

Free delivery for Windows-based control software LaserCAD, CorelDraw and AutoCAD direct output software (support PLT, AI, BMP,

DST, DSB, DXF formats).

Share