1

/

of

5

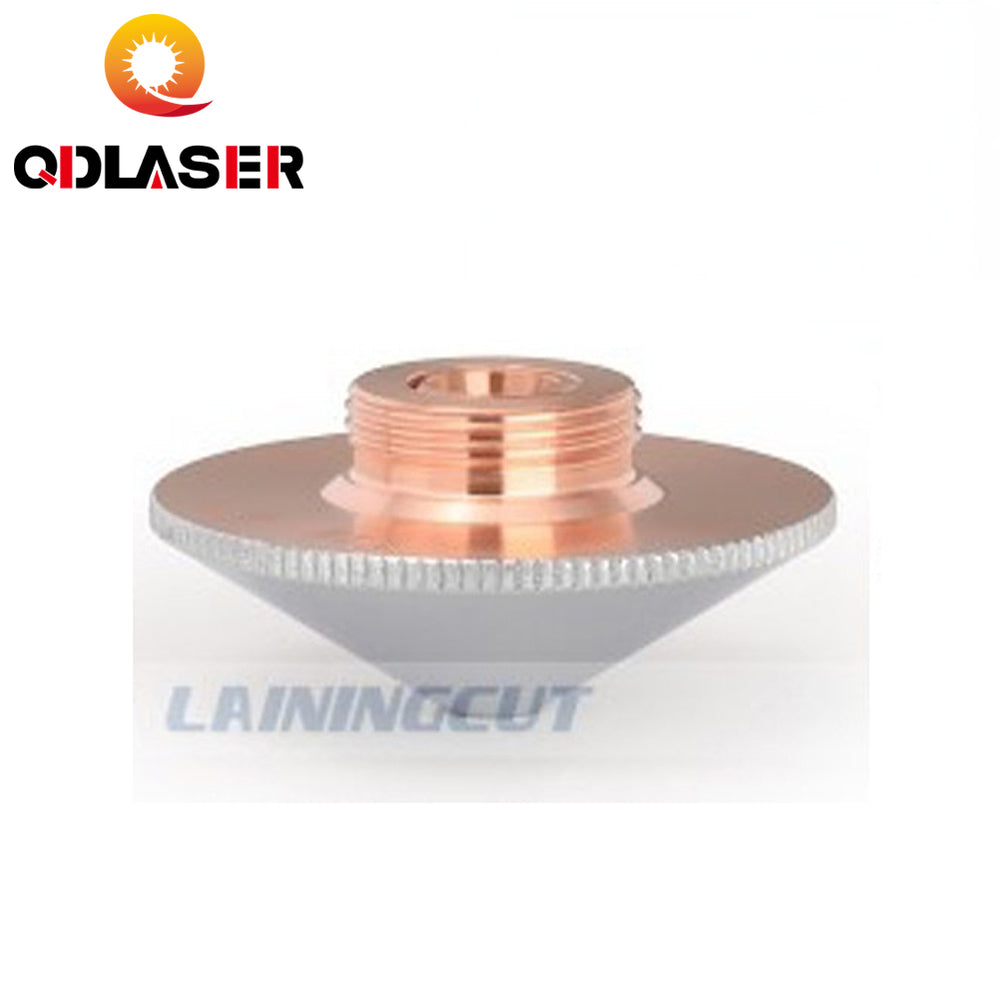

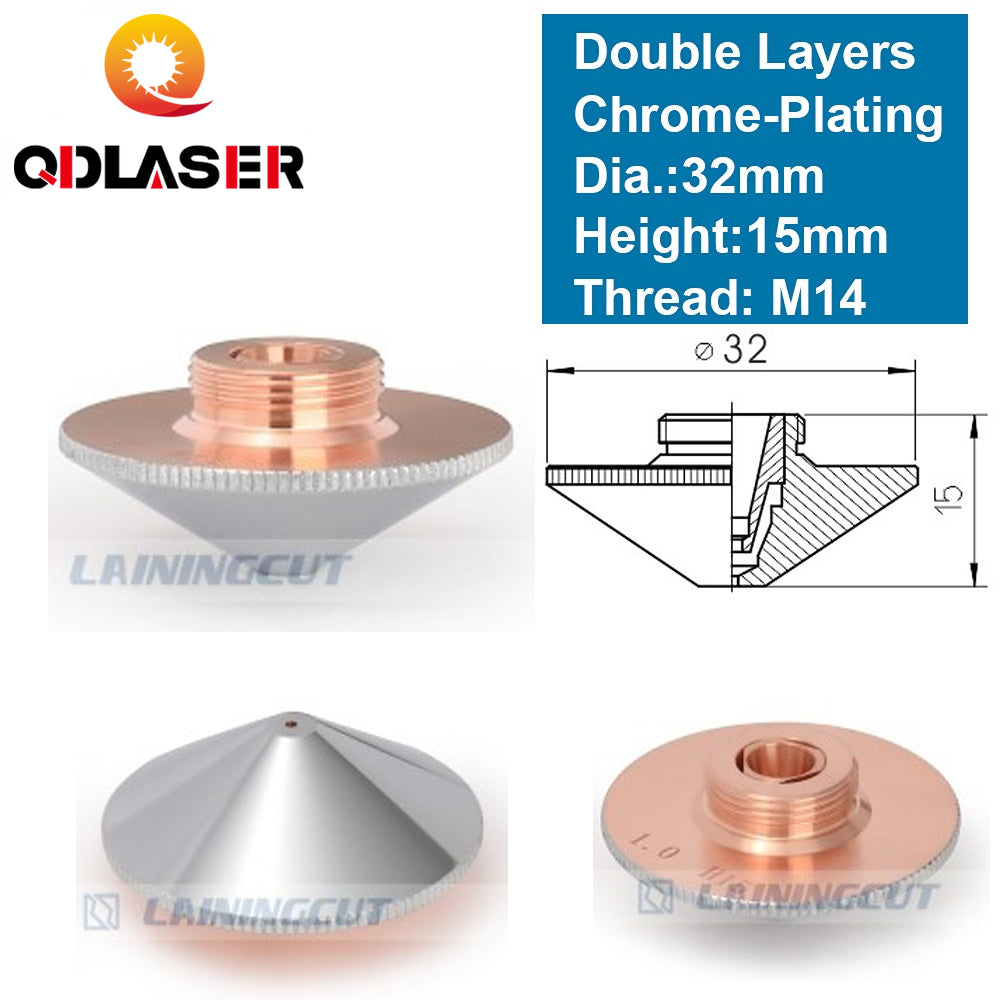

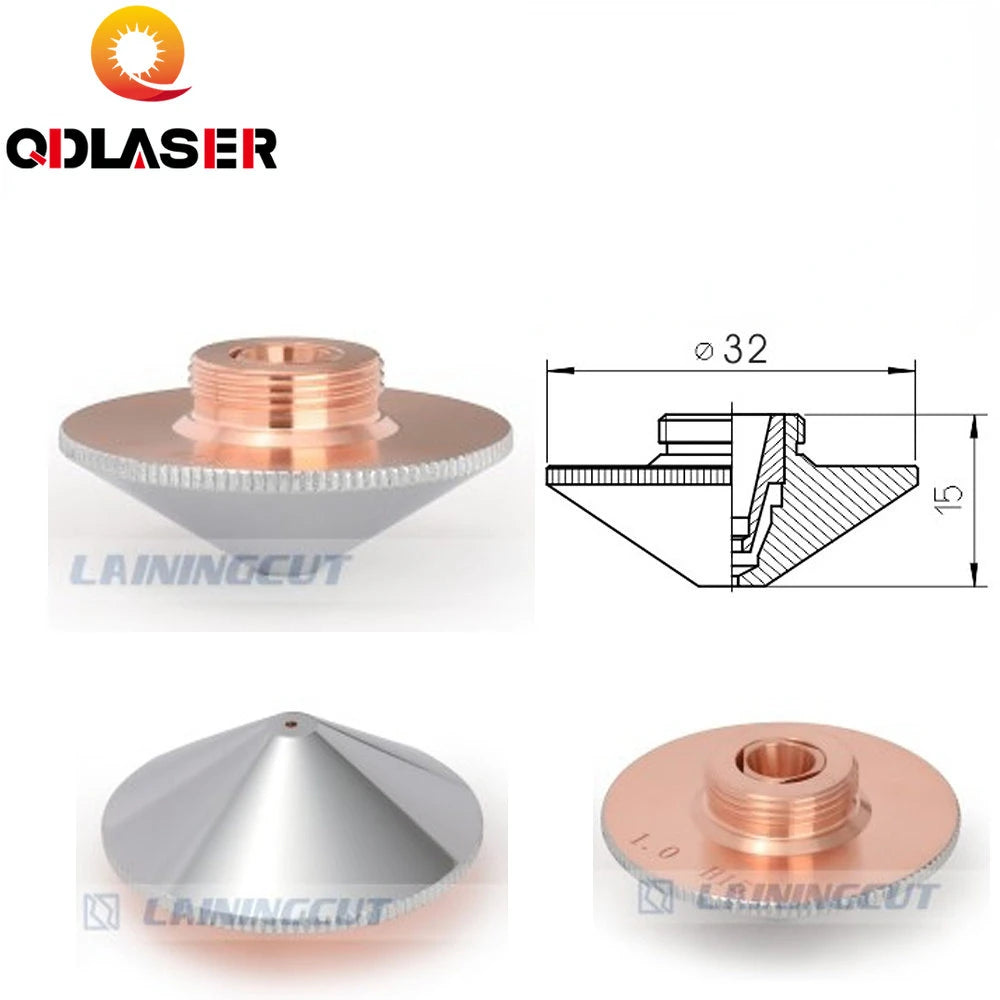

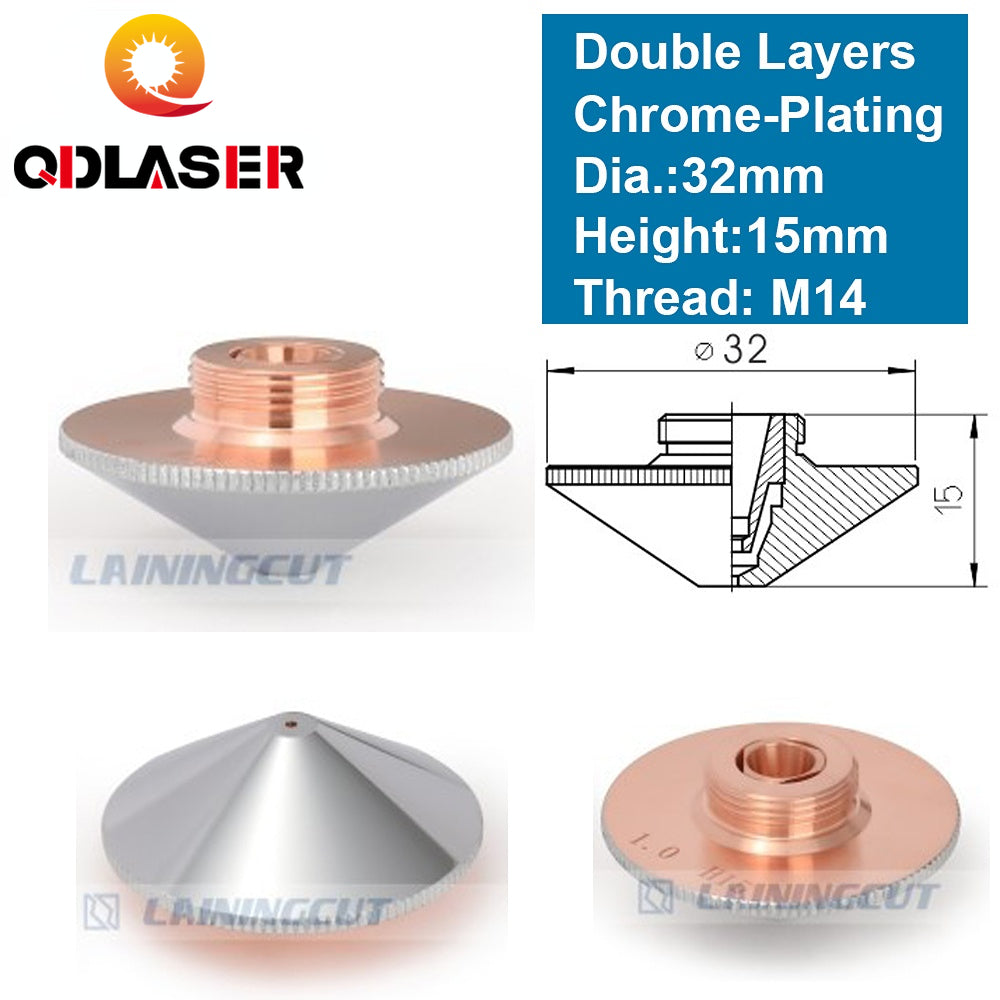

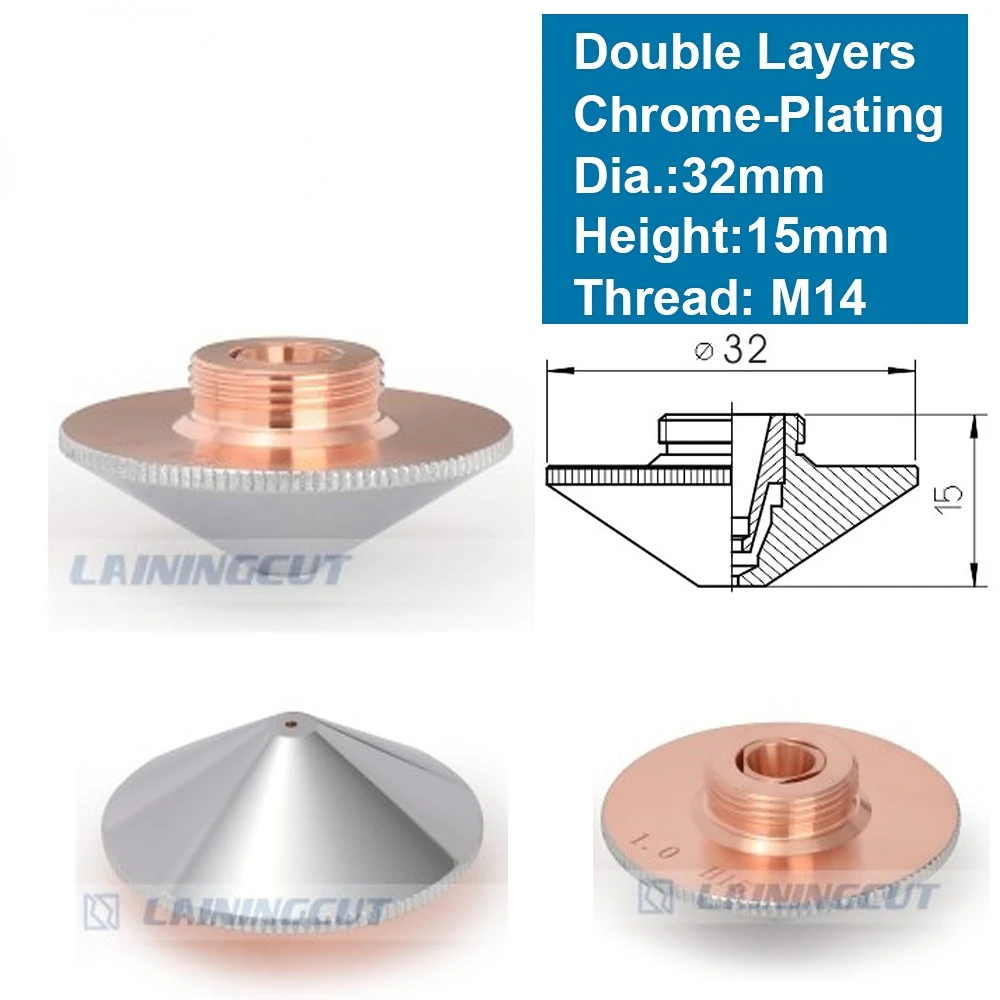

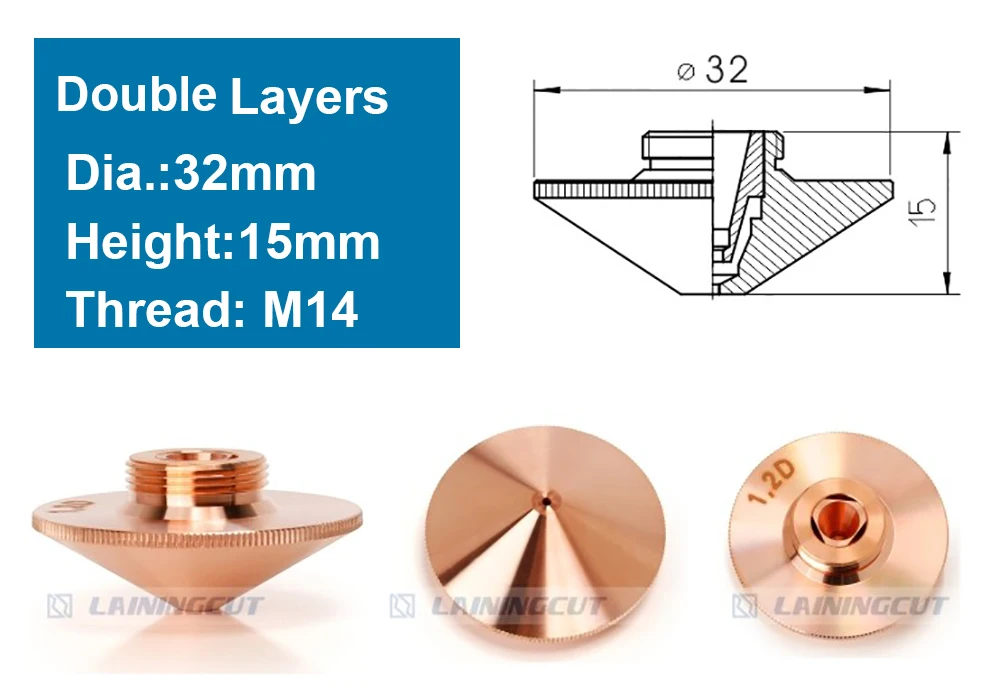

QDLASER OEM Double Layers Laser Nozzle Dia.32mm H15 M14 Caliber 0.8 - 4.0 for Precitec 1064nm Fiber Laser Cutting Head Machine

QDLASER OEM Double Layers Laser Nozzle Dia.32mm H15 M14 Caliber 0.8 - 4.0 for Precitec 1064nm Fiber Laser Cutting Head Machine

Regular price

$7.32 USD

Regular price

$7.32 USD

Sale price

$7.32 USD

Unit price

/

per

Couldn't load pickup availability

Products Description

QDLASER OEM Double Layers Laser Nozzle Dia.32mm H15 M14 Caliber 0.8 - 4.0 for Precitec 1064nm Fiber Laser Cutting Head Machine

The laser cutting nozzle can assist the gas to eject rapidly, which can effectively prevent the debris from falling upward and

thus protect the focusing mirror. At the same time, it controls the diffusion area and size of the gas, thus affecting the cutting

quality of the laser cutting machine. At the same time, the choice of the nozzle aperture size will vary according to the

thickness of the cutting material.

Single nozzle is used for melting cutting, that is, nitrogen is used as auxiliary gas to cut stainless steel and aluminum plate.

Double nozzles are commonly used for cutting oxygen, which uses oxygen as an auxiliary gas for cutting carbon steel.

Advantage:

l Made of high quality copper material, can provide stable signal transmission, high processing precision, high light inside the

stack surface, airflow barrier through, less slag, no burrs, cutting easily.

l The strict oxidation prevention process, copper bright, smooth surface, can effectively prolong the use of time.

l Suitable for market mainstream brands, such as PRECITEC, Han, laser, Wan Shunxing, Jin Yun, Dican, Hong Shan, Jia Qiang,

Chutian, thunder, high energy and other fiber laser cutting head.

1.Cutting thin plate (3mm below): choose diameter 1mm aperture nozzle, cutting effect will be relatively fine, and choose diameter

1.5mm aperture of nozzle will be thicker, and the corner of the place will be easier to stain.

2.Cutting plate (above 3mm): choose to use 1mm when the diameter of the nozzle aperture is not stable, because the cutting power

is higher, the relative cooling time is longer, the relative cutting time increases, with 1mm aperture diameter nozzle gas

diffusion area is small, so it is not too stable, but basically can still be used. The nozzle with a diameter of 1.5mm diameter

has a large gas diffusion area and a slower gas flow rate, so it is stable when cutting.

3.Cutting more than 10mm of the plate. At present, 2mm or 2mm diameter nozzle is usually chosen.

Note: Some 0.8/1.0/1.2/1.4/1.5/1.8/2.0/2.5/3.0/4.0 aperture size, please select need output aperture.

Packaging:

1pcs*Laser Nozzle (you chose model)

The laser cutting nozzle can assist the gas to eject rapidly, which can effectively prevent the debris from falling upward and

thus protect the focusing mirror. At the same time, it controls the diffusion area and size of the gas, thus affecting the cutting

quality of the laser cutting machine. At the same time, the choice of the nozzle aperture size will vary according to the

thickness of the cutting material.

Single nozzle is used for melting cutting, that is, nitrogen is used as auxiliary gas to cut stainless steel and aluminum plate.

Double nozzles are commonly used for cutting oxygen, which uses oxygen as an auxiliary gas for cutting carbon steel.

Advantage:

l Made of high quality copper material, can provide stable signal transmission, high processing precision, high light inside the

stack surface, airflow barrier through, less slag, no burrs, cutting easily.

l The strict oxidation prevention process, copper bright, smooth surface, can effectively prolong the use of time.

l Suitable for market mainstream brands, such as PRECITEC, Han, laser, Wan Shunxing, Jin Yun, Dican, Hong Shan, Jia Qiang,

Chutian, thunder, high energy and other fiber laser cutting head.

1.Cutting thin plate (3mm below): choose diameter 1mm aperture nozzle, cutting effect will be relatively fine, and choose diameter

1.5mm aperture of nozzle will be thicker, and the corner of the place will be easier to stain.

2.Cutting plate (above 3mm): choose to use 1mm when the diameter of the nozzle aperture is not stable, because the cutting power

is higher, the relative cooling time is longer, the relative cutting time increases, with 1mm aperture diameter nozzle gas

diffusion area is small, so it is not too stable, but basically can still be used. The nozzle with a diameter of 1.5mm diameter

has a large gas diffusion area and a slower gas flow rate, so it is stable when cutting.

3.Cutting more than 10mm of the plate. At present, 2mm or 2mm diameter nozzle is usually chosen.

Note: Some 0.8/1.0/1.2/1.4/1.5/1.8/2.0/2.5/3.0/4.0 aperture size, please select need output aperture.

Packaging:

1pcs*Laser Nozzle (you chose model)

Share