1

/

of

4

100W 130w 150W 1390 Co2 Laser Cutting Machine for Acrylic Plywood Cutting Engraving Ruida Control System Reci Laser Tube

100W 130w 150W 1390 Co2 Laser Cutting Machine for Acrylic Plywood Cutting Engraving Ruida Control System Reci Laser Tube

Regular price

$3,200.00 USD

Regular price

$3,200.00 USD

Sale price

$3,200.00 USD

Unit price

/

per

Couldn't load pickup availability

100W 130w 150W 1390 Co2 Laser Cutting Machine for Acrylic Plywood Cutting Enraving Ruida Control System Reci Laser Tube

The Pinnacle of Quality, The King of Functions

80W / 100W / 130W / 150W non-metal environmentally engraving & cutting solution

QD-1390i laser engraving machine is a fireproof model developed for production safety.

* Transmission structure

* Sturdy

The 2mm thick body is designed in strict accordance with the principles of mechanics, so that the rigidity and stability of the machine are sublimated perfectly. The net weight of the machine is 400KGS.

80W / 100W / 130W / 150W non-metal environmentally engraving & cutting solution

QD-1390i laser engraving machine is a fireproof model developed for production safety.

Processing industry and materials:

Suitable for high-precision high-gloss organic materials/acrylic products cutting related industries, advertising, lighting industry, photo frame woodworking industry, architectural model industry, crafts, decoration industry, clothing proofing, leather industry, shoes industry, furniture industry, packaging and printing industry, craft and gift industry, etc.

Advantage

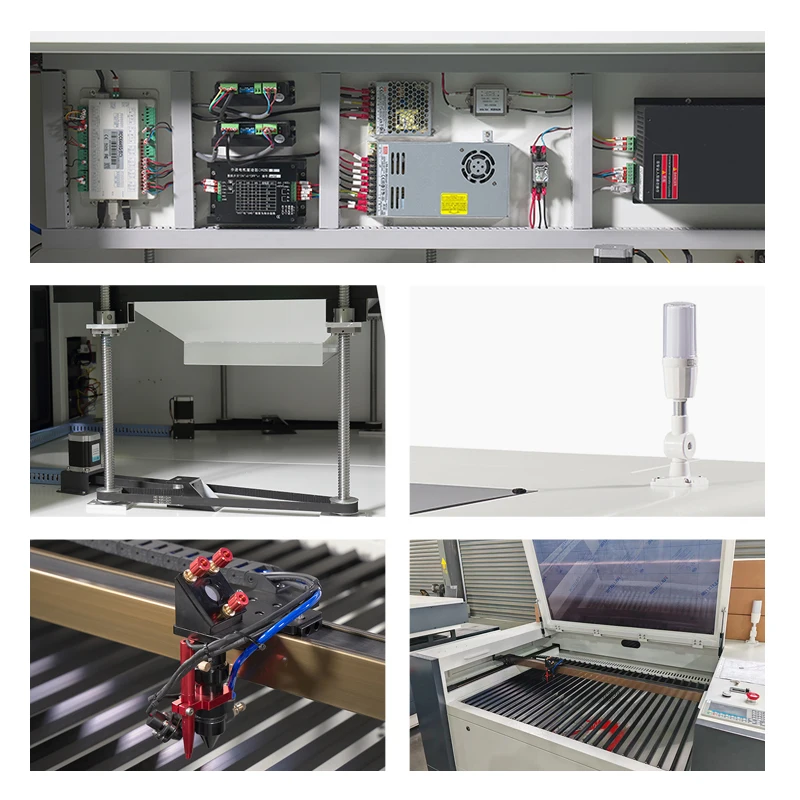

* Transmission structure

High precision slider group transmission structure, improve the motion performance and accuracy of the machine; 40mm belt and fully enclosed beam make the traction of the machine more uniform, higher stability, dust-proof and noise-free.

* Fire protection system

The machine has added intelligent fire prevention module and induction probe to prevent material burning in time and effectively. The whole system includes fire prevention module, induction probe, gas pipe, 600W air compressor, oil-water separator, air gun and operation indicator to ensure the safe operation of the machine.

The machine has added intelligent fire prevention module and induction probe to prevent material burning in time and effectively. The whole system includes fire prevention module, induction probe, gas pipe, 600W air compressor, oil-water separator, air gun and operation indicator to ensure the safe operation of the machine.

* Sturdy

The 2mm thick body is designed in strict accordance with the principles of mechanics, so that the rigidity and stability of the machine are sublimated perfectly. The net weight of the machine is 400KGS.

* Split structure design:

The body split structure design saves transportation space and reduces transportation costs (containers can be stacked in

three layers). Built-in bed structure reduces footprint by one third.

The body split structure design saves transportation space and reduces transportation costs (containers can be stacked in

three layers). Built-in bed structure reduces footprint by one third.

* Hydroelectricity separation:

The external circuit of the machine and the external water pipe and air path of the machine are separately installed on the left and right to prevent the circulating water of the machine from contacting the circuit, and the safety factor is higher.

The external circuit of the machine and the external water pipe and air path of the machine are separately installed on the left and right to prevent the circulating water of the machine from contacting the circuit, and the safety factor is higher.

Share